Precision Motion Systems

for Medical Technology and Industry

gKteso supports OEMs in building future-ready radiotherapy, imaging, and surgical systems. Our proven platforms, integration expertise, and certified production streamline development, minimize complexity, and ensure safe, compliant devices – enabling faster global launch and competitive advantage in precision medicine.

Our areas of expertise in Medical

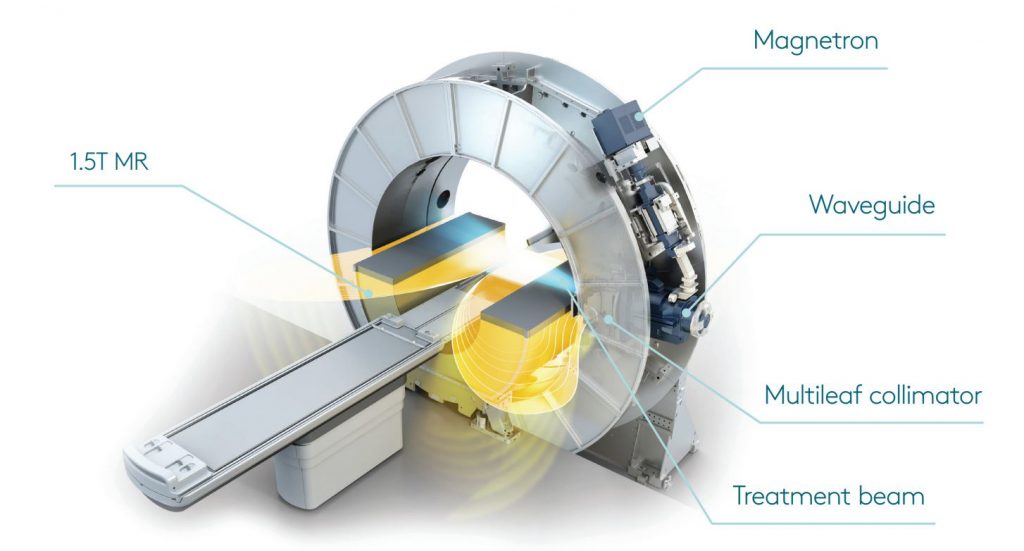

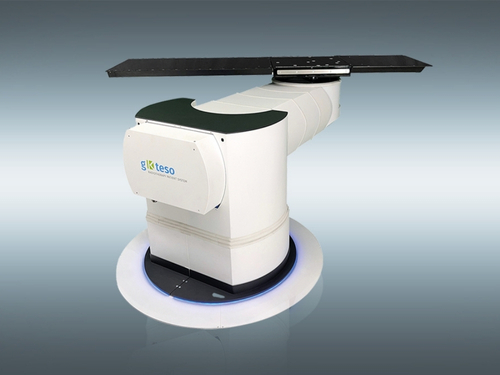

Radiotherapy Patient Positioning

gKteso’s modular RPS platforms deliver submillimeter patient positioning for stereotactic and MRI-guided radiotherapy. Seamlessly integrating with linear accelerators, they enhance targeting accuracy, streamline workflows, and improve patient safety – empowering clinics and OEMs to achieve next-generation treatment precision.

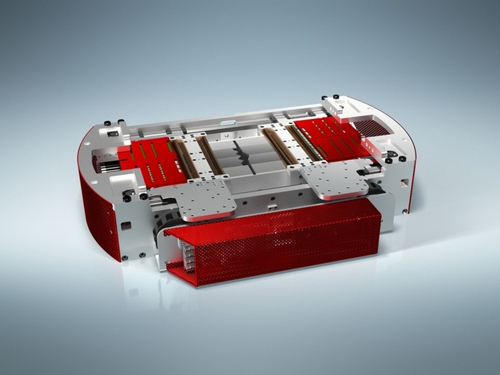

MLC Beam Shaping Systems

gKteso provides advanced Multileaf Collimators (MLCs) for accurate and reliable radiation field control. Our standard and customized beam shaping systems enable fast OEM integration, support innovative radiotherapy platforms, and ensure clinical precision. With modular design and proven engineering, gKteso helps accelerate development and deliver high-performance radiotherapy solutions worldwide.

Ophthalmology Motion Systems

Ophthalmology Motion Systems by gKteso deliver ergonomic, modular patient positioning for LASIK, PRK, SMILE, and advanced microsurgery. Engineered for seamless OEM and clinical integration, our CE-/FDA-compliant platforms ensure precision, safety, and smooth workflows – accelerating system development and global market access.

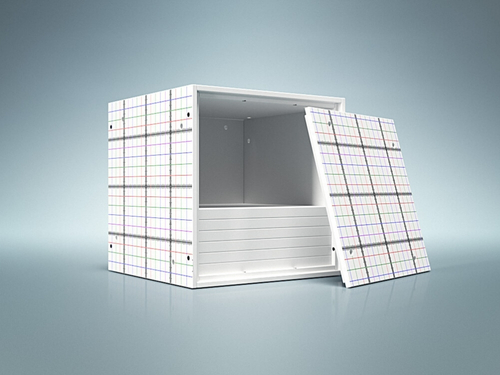

Water-Equivalent QA Phantoms

QA Phantoms from gKteso deliver reliable quality assurance and calibration for radiotherapy and imaging. Made from tissue-equivalent materials, they enable precise dosimetry, system commissioning, and end-to-end validation. CE/MDR and FDA compliance ensures safe global use. Ideal for clinics, OEMs, and research to achieve consistent, accurate QA results.

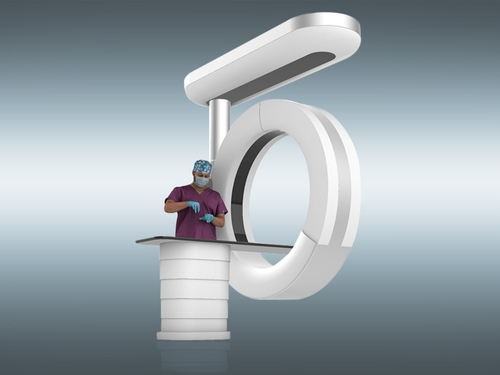

Interventional Radiology

gKteso designs advanced imaging solutions for minimally invasive procedures. Our ceiling-mounted and mobile systems provide real-time, high-resolution imaging, optimized patient access, and seamless hospital IT integration. Built for OEMs and clinical innovators, they support safer workflows, faster interventions, and CE/FDA-ready compliance.

OEM Solutions and Contract Manufacturing

gKteso helps medical technology innovators turn complex ideas into reliable, compliant products. We support the full journey – from concept transfer and prototyping to ISO 13485-certified production. With decades of engineering expertise and regulatory know-how, we enable faster market entry, precision manufacturing, and scalable growth for global MedTech OEMs.

Design as a Service

gKteso helps MedTech OEMs turn complex ideas into safe, user-friendly, and

regulatory-compliant products. From initial concept and rapid prototyping to

CE/FDA-ready, scalable production, our industrial design and engineering

expertise accelerate development, reduce approval risks, and deliver innovative

devices to market faster.

Our areas of expertise in Industrial

Deburring System

We design and build finishing systems for metallic and nonmetallic components. Using advanced grinding, polishing, and coating technologies, we produce surfaces with defined roughness values that meet demanding industrial standards.

Assembly Machines

Our assembly systems combine robotics, motion control, and integrated quality monitoring for precise and repeatable production. Each system enables reliable joining, fastening, or alignment of complex components in continuous operation.

EMC Testing

We develop test systems that detect and eliminate electromagnetic interference in electronic assemblies. Precise measurement and analysis modules ensure electromagnetic compatibility and compliance with international standards across diverse industries.

Waterjet Cutting

Our waterjet cutting systems process metals, plastics, and composite materials without thermal distortion. The systems achieve tight tolerances and clean edges, enabling the production of complex geometries for industrial and medical components.

About us

35 Years of innovative ideas

60 Employees

6,000 m² Production area

2 Locations in southern Germany

16+ MLC designs

50% of Ophthalmology OEM market

Smarter Solutions

for Maximum Quality

gKteso is an innovation partner for advanced motion and positioning systems. We develop and manufacture technologies that enable precise movement, stable processes and reproducible results. Our systems are used in medical technology, industrial automation and research environments, wherever accuracy and reliability define success.

Why Choose gKteso?

End-to-End Development

From concept drawings and early spec to certified production - gKteso offers complete in-house development for medical and industrial systems. Our integrated engineering and manufacturing ensure seamless processes, shorter lead times, and reliable scalability for OEMs.

Fully Customizable Solutions

Every project is unique. But the schedule is always tight. That’s why our platforms and components are modular and fully customizable - tailored to your technical, clinical, or regulatory needs. We turn your specifications into high-performance, CE/FDA-ready products.

Certified Quality

& Compliance

With ISO 13485 and ISO 9001 certifications, we guarantee the highest quality, traceability, and safety standards. Our compliance-driven approach ensures reliable documentation, risk management, and global market readiness.

35+ Years of Engineering Expertise

Decades of experience in precision motion, radiotherapy, and automation make gKteso a trusted OEM partner. Our proven track record and deep technical know-how ensure dependable, future-proof system performance.